Although frost-proof, this hose bib froze during the winter months. Water was running through the siding and freezing on the exterior walls. The copper stub protruded through the wall and was soldered to piping inside the basement.

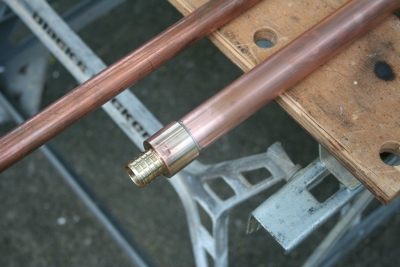

Here, the new hose bib is inserted through the exterior wall and soldered into place. With reasonable care, this fixture should last many years. The fixture was soft soldered using OATEY brand lead-free, silver solder.

ORMECO technicians are qualified to solder and braze copper. Our program is developed in accordance with the Copper Development Association (CDA) and ASME Boiler and Pressure Vessel Code (BPVC), Section IX Part QB.

NEW HOSE BIB INSTALL

This customer desired an additional hose bib. Exterior bibs must be freeze-resistant, lead-free, and equipped with a vacuum breaker. Additional International Plumbing Code (IPC) criteria requires all exterior wall penetrations be made water-tight (305.5) and rodent proof (304.4). Here, cross-lined polyethylene (PEX) tubing is connected to the hose bib underneath the house. Note the PEX barb is soldered to the end of the copper stub. A pipe sleeve (not shown), which is two pipe diameters larger than the pipe is required per Section 305.3 of the IPC.