If you would like to discuss possibilities, give us a call.

Drip Irrigation System

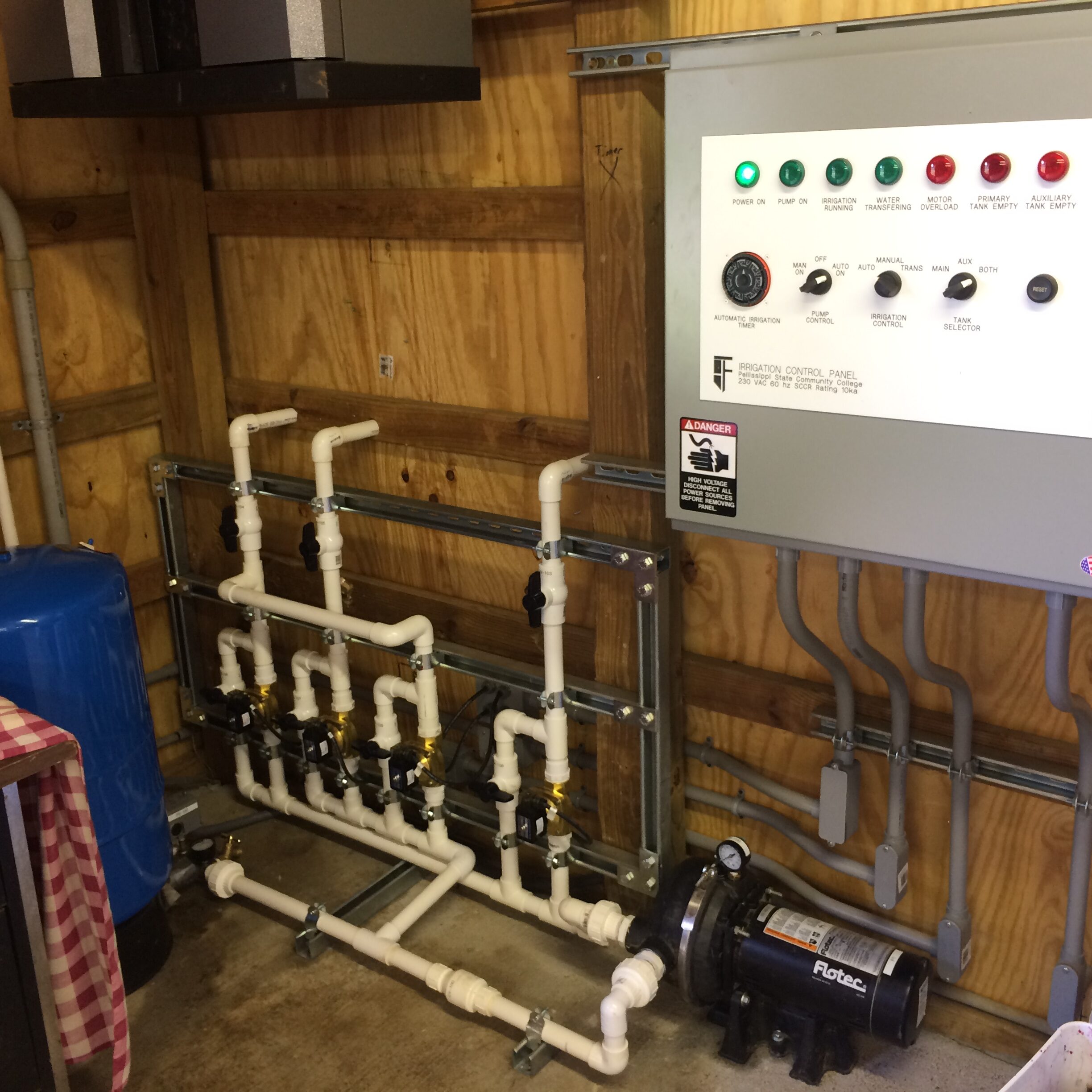

An upgrade to an existing irrigation equipment, this system is designed and built to meet rigorous industrial standards. There are three supply cisterns which hold up to 4,500 gallons; the cisterns collect rainwater. This water is then gravity-fed to the irrigation distribution piping. The control system utilizes a 24-hour/7-day timer for automatic drip irrigation. Water can be transferred between the various tanks and there are float switches to prevent the system from being run dry. Line pressure is maintained by a pressure tank, and a centrifugal pump maintains the tank pressure.

The controls were designed in accordance with UL 508A; the piping meets the requirements of Section 1303 of the International Plumbing Code (IPC).

The Obsolete System

The existing irrigation system was in rough condition; it rarely worked properly.

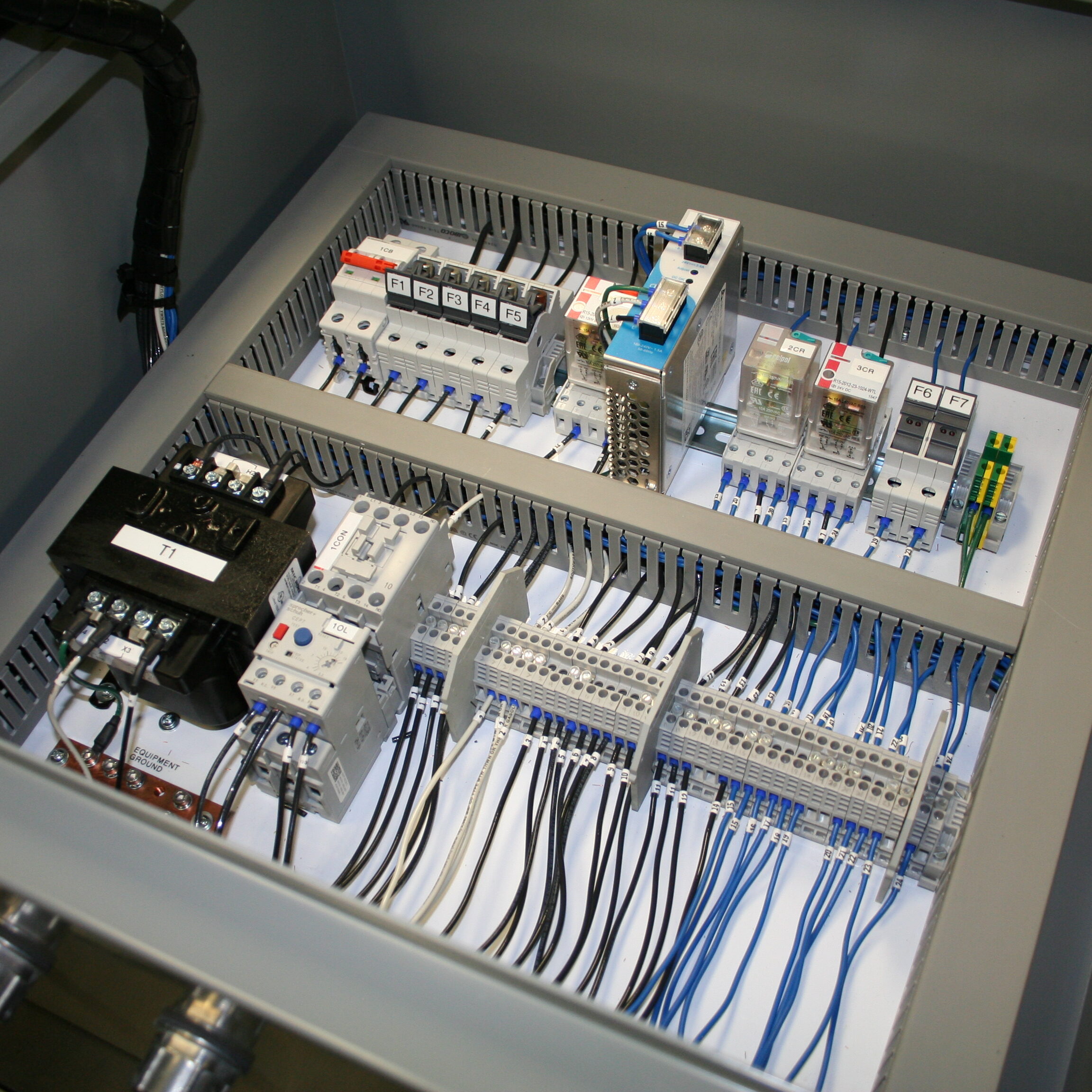

New Electrical

As part of the upgrade, new electrical wiring was installed; this included adding low-voltage float switches to the tanks.

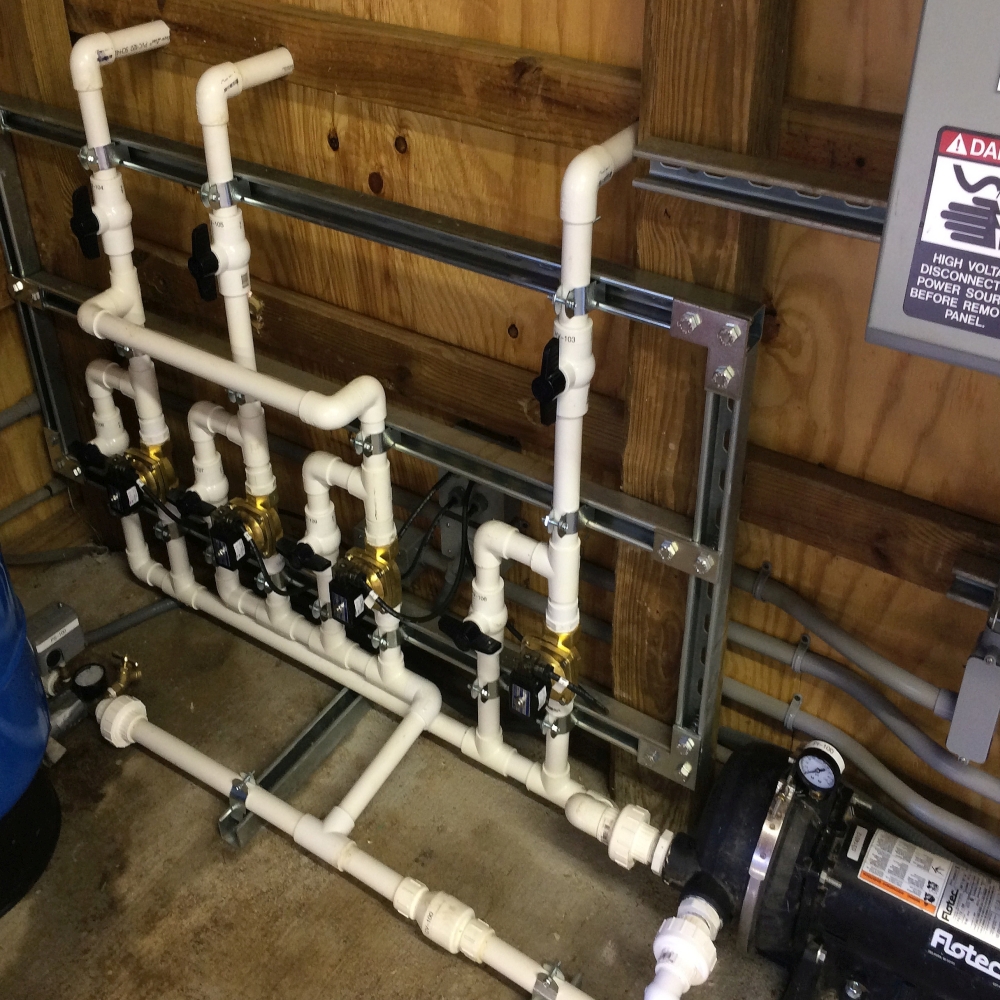

New Piping

New distribution piping, including directional control valves, was built.

Control Panel

A new control panel was fabricated; this met the requirements of UL 508A.

New Valve Manifold

New distribution piping, including directional control valves, was built.

COMPLETED SYSTEM

This robust, industrial-grade system should last for years. It can be serviced using non-proprietary components.